Don't mean to bother you Matt, as we all know you are very busy but estimated how far down the line is OST?

About 75% of it is done.

What remains, is the part that starts getting complicated.

For example, a

proper shift firmness adjustment. I'll explain a little of what we are up against, from the aspect of logic coding.

Anyone who has tuned a 6.4L (or 5R110 for that matter) knows that in order to tune the transmission properly, there are multiple pressure tables and slip times that need to be adjusted simultaneously, in two opposite directions, for the shift to be syncronized properly. At bare minimum, 3 slip time tables and 2 shift pressure tables.

As you can imagine, it isn't just as easy as as applying a +(x)% and -(x)% to each of them to dial the shift in properly. If we wanted an easy, half-ass solution, I'd use an SCT device. In order to do it properly, there needs to be a specific mathematical formula derived to describe the relationship between shift pressure adjustments (both oncoming and offgoing) and the resulting affect on slip time from said pressure adjustment.

When a thorough study of those relationships is done (both in hypothetical theory and real-world results) those formulas come down to a fairly complex three-variable logarithm, in order to truly model shift characteristics accurately.

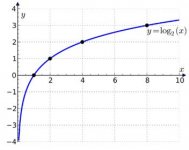

Just imagine something like the following, where "y" is the time required for a shift to complete (slip time) and "x" is the oncoming start pressure for the shift:

y=-(log_2(x))

Take a look at the graph below, and imagine the Y axis being numerically inverted to describe slip time. As you can see, the relationship reaches a point to where adding more shift pressure no longer has any effect on speeding up the shift, because you've reached the mechanical limits of the parts involved.

This was a very rough starting point for us, and the current equation is much longer. We are still working to tweak it further. What is so time consuming, is coming up with models for this from scratch.

Any hack can buy SCT or MCC and start gouging at tables with multiplication. Yes, it works, but part of our motivation for working on this is to provide something

truly better.

The same applies for the injection pulsewidth changes, for larger nozzles. It's sometimes "close enough" to multiply the top 2/3 of a pulsewidth table for larger nozzles, but a careless job results in either a sluggish truck or a smoky mess. And you certainly can't apply global multiplication to the lower portions of the table, to compensate for pilot injections and so forth, because it's incredibly touchy.

In order to accurately model the relationship between nozzle size and pulsewidth, it becomes the same issue as described between shift pressure and slip time adjustments. No matter how large of a nozzle you install, the actual piezo actuation time plays a large role in the pulsewidth tuning, and this relationship isn't proportional across the board. At tiny injections (such a pilot injection) and at low injection pressures (close to idle) the piezo actuation can account for GREATER than 99% of the total injection time. Pull the pulsewidth down 1%, and now you have no pilot injection whatsoever. Despite the sensitivity, it still needs to be tuned- and this is done through extremely careful math. The equation to accurately describe these relationships starts to look somewhat similar to the math described before, with relationships between piezo actuation time, injection pressure, nozzle size differential, and fuel temperature.

I've often, in this thread, described this software as an alternative to full custom tuning that carries 80% or more of the capabilities, and is entirely on-screen with easy selections. Many are skeptical of this, because it's not something that has really been done before. Typically, this kind of work requires an educated user performing educated guesses to get it right.

What we are doing here, is removing both the educated user, and the educated guessing, and replacing it with

good math. Math needs no guidance and math makes no guesses. And in the end, I truly believe it will change how these trucks are tuned.

Sorry for the diatribe, but it gives some insight as to why this is time-consuming.