madpowerstroke

New member

Hello, members, I had a chance to get my ypipe out and took a good look at it. I figured a way to do a very nice and cheap mod that gains results. I posted on a different site and now posting on this one also. I want all 6.0 powerstrokes and shops to see and try the mod. On the other site I got slammed alittle because of me saying that it will reduce backpressure, increase spool(less lag) and lower egt's( not huge amount maybe 25-50degrees). I didn't provide any data to support the claims, the reason I don't have any data is simply because for one it is a proven 101 hot rod trick that reducing restriction and improving air flow will give you all the benifits I listed. The other reason is that I'm not selling this mod I'm sharing info and method for anyone to do it, so why do I have to spend money on flow bench to provide any data.

Anyone can accomplish this mod or have any shop do it, and gain results, I'm sharing the mod to help the 6.0 powerstrokes become better, and it's such a easy mod that it wouldn't worth selling it. The mod I have done in under 1 hour, and for my own experiences have seen a nice difference, and so will anyone else. The mod will benifit anyone with stock turbo tuning to a highly modified truck, and like I stated before it's cheap, cost is very low, not like buying or building a set of ypipes to get just about same results.

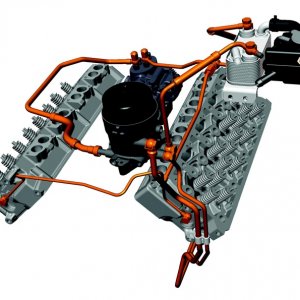

The mod itself is simple, if you get a ypipe you will noticed that on the inside of the colletor where pipes meet there is actually a 90 degree dam due to the collector shape. One one side it blocks the pipe about 1/4 -1/2 inch on other side it's about 1/2-3/4. That amount of exhaust gasses being forced to hit the 90 degree and then deflect towards center to cause turbulence to the exhaust gasses driving straight to the center. By smoothing and getting rid of the restriction the outter gasses now flow right into collector and the turbulence is now gone. The flow of exhaust gasses now have been allow to go right in the turbo to provide the muscle. I'm just explaining for members to understand, I know that the shops and vendors know all this stuff.

I also don't know if anyone has ever done this mod or figured before me, but I just wanted to share it with everyone. I figure the mod on my own and didn't research to see if anyone else had done it before. Here are some pictures before and after to get an idea of what I did, and what to do. Thanks and hope this helps everyone with a 6.0 powerstroke. I also want to thank Dale for using some of his pictures they are better than mine, he took them as he was trying the mod on his truck.

More pics next reply::

Anyone can accomplish this mod or have any shop do it, and gain results, I'm sharing the mod to help the 6.0 powerstrokes become better, and it's such a easy mod that it wouldn't worth selling it. The mod I have done in under 1 hour, and for my own experiences have seen a nice difference, and so will anyone else. The mod will benifit anyone with stock turbo tuning to a highly modified truck, and like I stated before it's cheap, cost is very low, not like buying or building a set of ypipes to get just about same results.

The mod itself is simple, if you get a ypipe you will noticed that on the inside of the colletor where pipes meet there is actually a 90 degree dam due to the collector shape. One one side it blocks the pipe about 1/4 -1/2 inch on other side it's about 1/2-3/4. That amount of exhaust gasses being forced to hit the 90 degree and then deflect towards center to cause turbulence to the exhaust gasses driving straight to the center. By smoothing and getting rid of the restriction the outter gasses now flow right into collector and the turbulence is now gone. The flow of exhaust gasses now have been allow to go right in the turbo to provide the muscle. I'm just explaining for members to understand, I know that the shops and vendors know all this stuff.

I also don't know if anyone has ever done this mod or figured before me, but I just wanted to share it with everyone. I figure the mod on my own and didn't research to see if anyone else had done it before. Here are some pictures before and after to get an idea of what I did, and what to do. Thanks and hope this helps everyone with a 6.0 powerstroke. I also want to thank Dale for using some of his pictures they are better than mine, he took them as he was trying the mod on his truck.

More pics next reply::