- Joined

- Dec 28, 2020

- Messages

- 271

- Reaction score

- 51

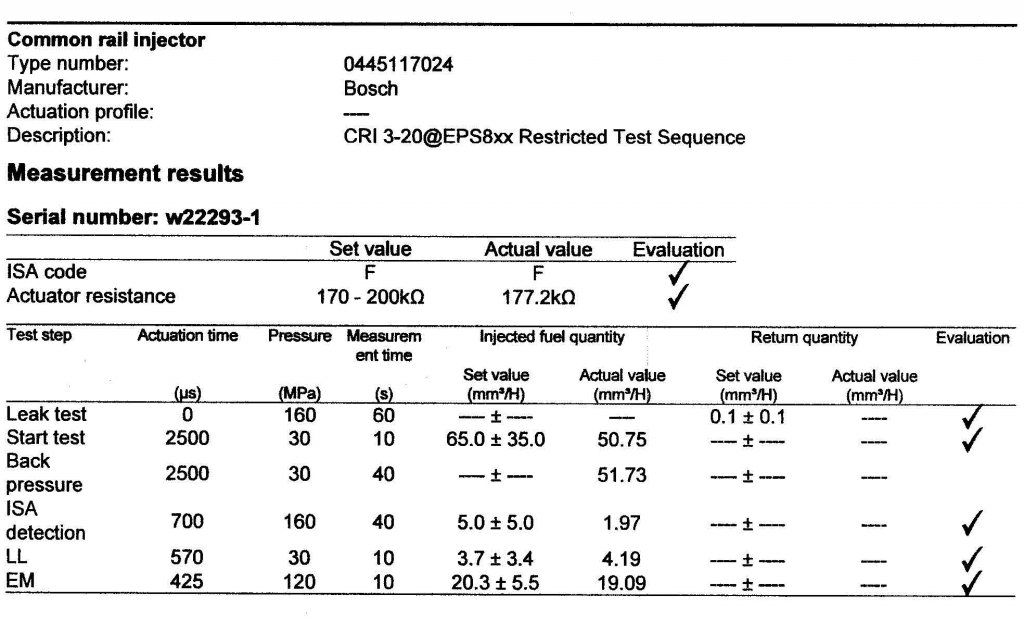

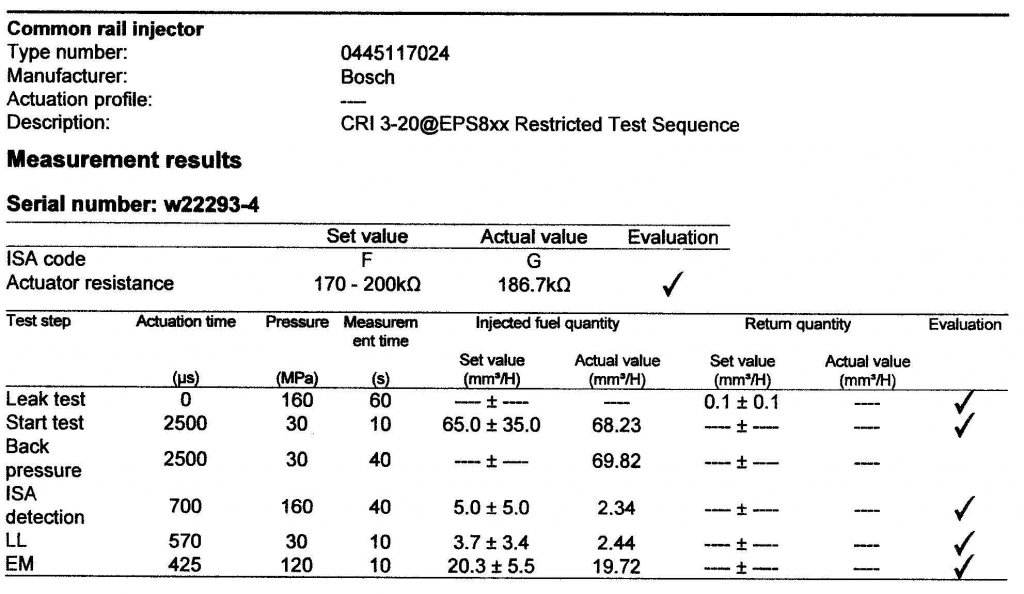

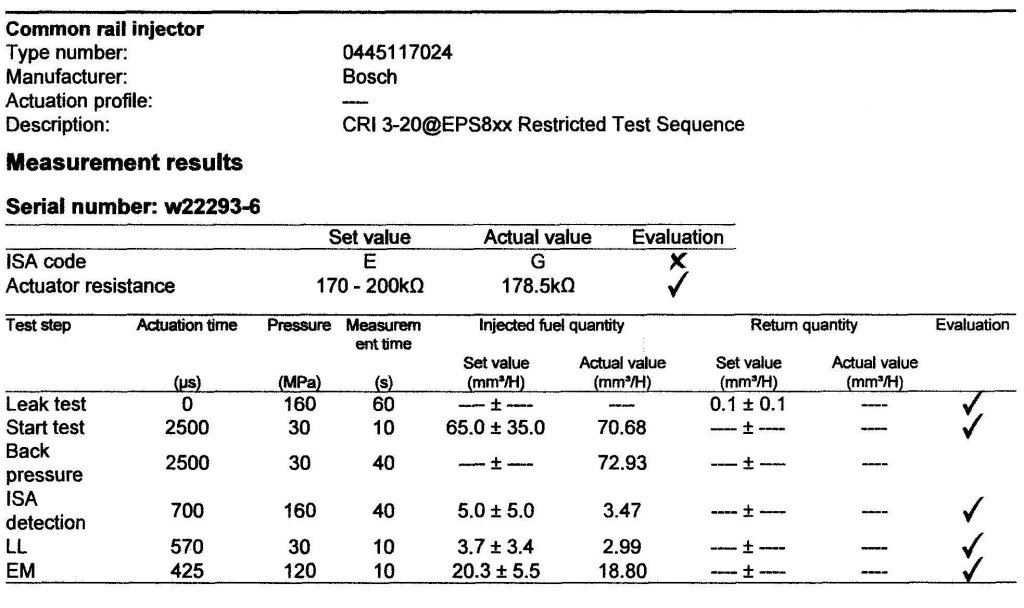

For kicks here are the results from 3 of the injector tests.

Good, marginal and fail.

Good, marginal and fail.

LPFP didn't change till 17s with the panel filter.I keep thinking someone will pop in and say, hey when I hook my scanner up I show 59 psi KOEO or something like that.

That 42 psi has always seemed weird to me.

The low pressure switch and pressure sensor are two different things. I would think the Fuel pressure would have to affect something.

As far as starting I suppose I could have a bad switch and a bad pressure sensor. LP switch stuck off. and PCM only looks at the LP switch?

But on the other hand, why haven't I burnt up the CP4 by now if that were the case?

This stuff sucks. When you don't do it everyday for a living the stupidest things can trip you up. Looks like most people online give up and go to the dealer.

When I hook up (a different scan tool) to my 2016 it reads like 350 psi KOEO. So I need to grab one of my other scanners or didn't they change the LPFP in 2015?

Don't know yet. But I will find out.

I have not tried LPFP yet. I am kind at that point out of desperation.LPFP didn't change till 17s with the panel filter.

did you try a low pressure fuel pump? Have you monitored both fuel pressures when driving around to see how far they drop when on the throttle hard?

Yes it is timed, at least like it was. Little confusing at first because 2 marks on both the gears, but I put it back the way it was.Did you time your hi pressure pump correctly? I’ve never done it wrong, so I can’t say what will happen, but it’s something to check. Also, does it have rpm and sync and all that good stuff? Could be a bad cam sensor or something

Sent from my iPhone using Tapatalk

Yes it is timed, at least like it was. Little confusing at first because 2 marks on both the gears, but I put it back the way it was.

I will have to check the other readings again. Pretty sure it did.

One thing another person mentioned to me got me to thinking about my return fuel. Kind of wondering if I can take the return line off at the LPFP or even tank and run it into a bucket and see what happens. That is something I haven't done yet.

View attachment 187175

Well that is interesting. That is exactly how it came apart. So I put it back together that way.That is off. 180 degrees off. You use the 2 marks on the pump gear to the 1 mark on the cam gear. If you turn the motor over 360 degrees, the single mark will be up on the cam gear.

Sent from my iPhone using Tapatalk

Well that is interesting. That is exactly how it came apart. So I put it back together that way.

The drive gear never left the housing. Keyway was on top on both new and old pumps.

So if that is truly off it has been that way for over 140k miles, meaning it must not matter.

Well that is interesting. That is exactly how it came apart. So I put it back together that way.

The drive gear never left the housing. Keyway was on top on both new and old pumps.

So if that is truly off it has been that way for over 140k miles, meaning it must not matter.

I will add it to my todo list.What I would do, to rule it out, pull the vacuum pump again, rotate the motor to that spot, pull the pump, and turn the motor over until the single mark is up, put the gear in, and bolt the pump back up and see if it’s better

Sent from my iPhone using Tapatalk

New vcv. No change.

I think I am at the point of another cp4 or pcm?

Cp4 is stupid. It turns it should pump. Even if it is pumping air. And if it was just air I should see a blip on my rail pressure right?

Yet nothing.

So I thought, what if it isn't spinning at all.

Since I am headed towards pulling it out.

Got the vacuum cover off. Verified timing is correct. Shot a video. Pump is spinning.

I'll let it stew a couple days but I will probably warranty out this cp4. Unless someone can point me a different direction.

View attachment 187186

I can swap it, I got timeSo, first off, the timing is not correct. You are 180 degrees off from how you had originally set the timing. The pump is in the same visual spot, but possibly incorrect inside. Turn the motor over to where you originally set the timing, remove the gear, turn the motor over to where it is now, and then reinstall the gear. Once again, I am not sure this is your problem, as I have never installed one incorrectly. However, it is not right, so do it right. If that fixes it, great, if not, then continue with diag.

Another thing, how long has this thing run since you have done the work? It may still have air in it.

But fix the ****ing pump timing before anything else, it will take 5 damn minutes for it to be correct instead of hmmming and hawing about what could be the issue. There is something not right, for sure, 100%, fix that and then retest. Shit, pulling the gear off, you don’t even have to crack the system at all…

Sent from my iPhone using Tapatalk