Josh@DirtyDiesels

New member

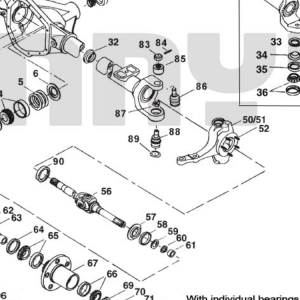

Thanks for the pic... so you just install that over the OEM gaskets? That must just crush.

Those look like UFC heads? Do you know what kind they are?

I really like the Oring option. It seems to add a little extra give for when the studs stretch under high cylinder pressures

Yes just install it over stock gaskets. UFC heads? Fill me in? to the best of my knowledge they are just stock heads.