Its not a typical diesel pump but Tarm had a cool thread out awhile ago where he used an 044...http://powerstrokearmy.com/forums/showthread.php?t=4230&highlight=bosch+pumps

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuelab or 2 Bosch pumps

- Thread starter mandkole

- Start date

David N

Active member

I love my dual stock pumps. They keep pressure with my 250/200's and I like the feeling if one ever fails, the other will at least get me home.

I hope. LOL

I hope. LOL

01PSD

New member

Its not a typical diesel pump but Tarm had a cool thread out awhile ago where he used an 044...http://powerstrokearmy.com/forums/showthread.php?t=4230&highlight=bosch+pumps

Thanks

The SX pump is still running as if nothing has happened...hmmm. Its taken the pressure off needing an immediate solution, but its trying to tell me something.

Im heavily leaning to a 2 SD pump setup. I have no doubt it will supply everything that I need with rock solid reliability. Plan for now is to start gathering components. I will be moving the pumps back to where the filters are, running a battery power supply, swapping out some hose and tidying up the top of the motor.

Im heavily leaning to a 2 SD pump setup. I have no doubt it will supply everything that I need with rock solid reliability. Plan for now is to start gathering components. I will be moving the pumps back to where the filters are, running a battery power supply, swapping out some hose and tidying up the top of the motor.

psduser1

Active member

I have an almost complete setup if your interested. It would get you a second pump, all the filter plumbing, most of the wiring and relays etc. Pm me if your interested. int:

int:

Chvyrkr

Active member

- Joined

- May 18, 2011

- Messages

- 2,204

- Reaction score

- 0

A few strategically placed taps of the hammer, the SX pump comes back to life. It acts now like nothing has happened.

Good thing its not a DD... I have to drive around with a hammer LOL

Why don't you take it to a starter/alternator rebuilder and see if they can do anything with it?

I didnt realize that starter/alt guys messed with fuel pumps. I suppose the motor side is fairly similar.

I took the truck out yesterday and put 20-30 miles on it. The fuel pressure gauge gave some very random and minor (1-2 psi) wiggles in the needle, but nothing else. The needle didnt go anywhere on some full throttle interstate onramp blasts in the max effort tune. It was the first time Id had it in the 200 tune since the track day last spring...

On the other hand, the 17* pump got a workout...thats for another thread.

I took the truck out yesterday and put 20-30 miles on it. The fuel pressure gauge gave some very random and minor (1-2 psi) wiggles in the needle, but nothing else. The needle didnt go anywhere on some full throttle interstate onramp blasts in the max effort tune. It was the first time Id had it in the 200 tune since the track day last spring...

On the other hand, the 17* pump got a workout...thats for another thread.

Dual SD pumps...

One goes down your still getting home.

One goes down you're finding the nearest Napa to replace it.

I'd like to change mine up to a main pump with a low pressure trigger to kick on the second one... could do that with the new isspro programmable trigger.

One goes down your still getting home.

One goes down you're finding the nearest Napa to replace it.

I'd like to change mine up to a main pump with a low pressure trigger to kick on the second one... could do that with the new isspro programmable trigger.

4.0l sahara

New member

fuelab gets my vote.

The SX pump needs a bullet in its head... it was a good pump and was impressed that it ran as long as it did. Good thing it happened close to the house and I got it running enough to get it home. I was headed on a 350 mi trip the next day and got out my FILs OBS to get it done.

Getting the fuelab on order this morning... I decided to do this as it will be totally drop in for me, I put few miles on it, and Bosch availability is sketch right now.

On a side note, I will be absolutely rewiring the pump to get relayed battery power. I really think this became an issue with the old pump as it had (stock) baby wire gauge and ran through the whole harness. With the pump is dying and building resistance, the high voltage is everything to keep it running.

Getting the fuelab on order this morning... I decided to do this as it will be totally drop in for me, I put few miles on it, and Bosch availability is sketch right now.

On a side note, I will be absolutely rewiring the pump to get relayed battery power. I really think this became an issue with the old pump as it had (stock) baby wire gauge and ran through the whole harness. With the pump is dying and building resistance, the high voltage is everything to keep it running.

littleredstroker

New member

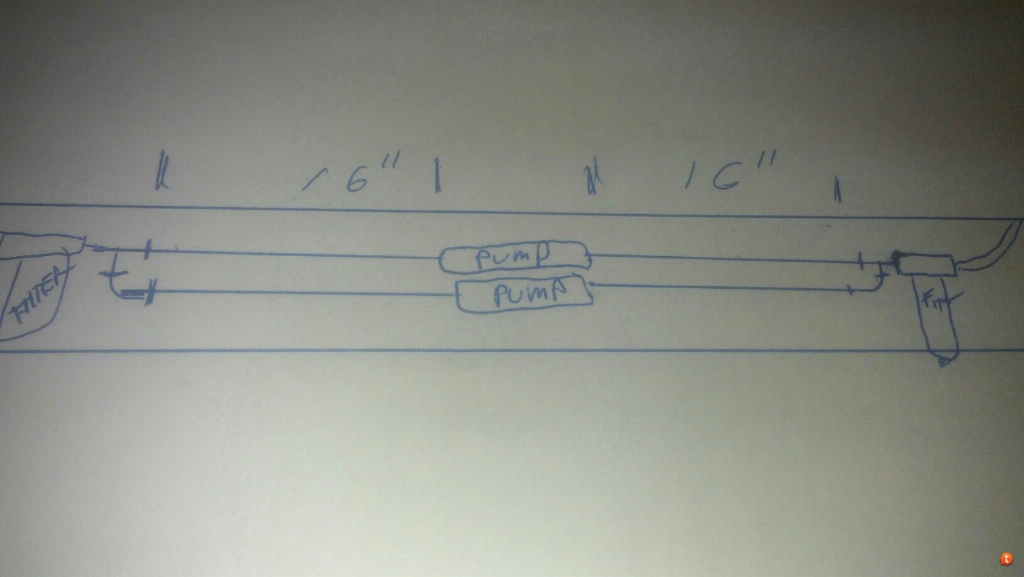

Forgive the 4th grade drawing. I spaced everything out on mine. 16 inches or so between pumps and filters, used a T and a 90 coming out and going in to each filter base. Looks a lot cleaner than a cluster bomb of pumps filters firings and wiring. And is a lot easier to work on IMO

Sent from my HTC PH39100 using Tapatalk

Lines have been re routed.

Blue line from sump, pre filter, then split to pumps, final filter.

Filter bases have two inputs and two outputs.

But you get the idea.

Bought the two pumps off flea bay.

One went out on me and I noticed it drop press to 50 psi during hard run.

With 350,200s on a low hp tune.

Pulled over and what do ya know one was not working.

Started it back up and drove it home.

I like the insurance of being able to get home.

Pair that with oem pumps, and you're golden.

Forgive the 4th grade drawing. I spaced everything out on mine. 16 inches or so between pumps and filters, used a T and a 90 coming out and going in to each filter base. Looks a lot cleaner than a cluster bomb of pumps filters firings and wiring. And is a lot easier to work on IMO

Sent from my HTC PH39100 using Tapatalk

No "T"a needed with the multiple input output filter bases.

littleredstroker

New member

No "T"a needed with the multiple input output filter bases.

I agree. if that's what you have, but I am very jew and built mine with as many free parts as I could

I hear ya-- I had a twin pump plan but got put back to sleep when the other pump kept running..lol. Now its dead and gotta go now. No Bosch in stock. If this pump lasts 7-8 years like the old one did, Im fine with that.

Ron's Power Stroke

Member

i just got my driven diesel fuelab fuel system for my truck...both of my filter bases has 2 ports in and 2 ports out...one port will be used for the fuelab..the other with the stock pump on a switch.... ill have the best of both worlds this way...like said a few post back... you don't hear of many fuelab fail threads...should be able to flow some fuel with the bowl delete block and the banjo bolts.....

one port will be used for the fuelab..the other with the stock pump on a switch....

Not a bad idea, in fact a decently running used pump would suffice. I really wanted to take the time to do this up with new hose and everything, but the fuelab will slide in the same clamps as the dead pump so its a minor job for now then I could clean it all up later with the second pump.

i just got my driven diesel fuelab fuel system for my truck...both of my filter bases has 2 ports in and 2 ports out...one port will be used for the fuelab..the other with the stock pump on a switch.... ill have the best of both worlds this way...like said a few post back... you don't hear of many fuelab fail threads...should be able to flow some fuel with the bowl delete block and the banjo bolts.....

Something to think about...

Isspro EV-2 fuel pressure gauge, with the new programmable trigger... Wire that second pump to that trigger via a a relay. Have the relay turn that pump on if the pressure drops below X pressure (50 or so) and have the warning light come on if the pressure drops below 50 as well...

Once I have time to change mine it will be set up to run a single Bosch 90% of the time, with the second pump turning on when the pressure drops below 62psi...