FWIW- The setup I'm

learning on...

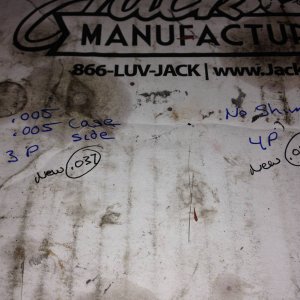

PTE 46mm gate w/25.5 psi spring pack

Turbosmart Diesel Boost tee

76mm inducer/200% nozzles

ZF6

street driven truck

Controller plumbing-Boost reference port on turbo compressor housing->Turbosmart Boost Tee->Bottom of WG. Top of WG vented to atmosphere.

I blab all that, because I think it's key to realize how you set the gate up, is probably somewhat application dependent, and how the WG is plumbed.

It's embarrassing to admit...but after installing a new boost tee with proper fittings, my BP to Boost ratio is much more in line with what I observed/read from other folks setups, as am 1:1 to nearly 40 psi now in a non transient/stabilized state. Chasing boost leaks is a rookie move I know, but the basic stuff just keeps biting me in the azz over and over again with my turbo/wg. Hopefully that'll put the exclamation mark on this issue for someone else.

Back to the OPs question though...my two main concerns were transient turbo response with a large turbo/street driven/manual trans truck. So the heaviest possible spring pack went into the gate (too be perfectly honest, it's the one Jake put in the gate, so he's the genius/dummy

...and I just rocked it 'cause I knew he was smarter than me on this issue, as it's the first time I ever ran a gate). When the truck was run without a boost ref tee, and the turbo compressor housing boost ref port was plumbed direct to the top of the gate, the turbo was extremely light switchy...either off or on. Nearly impossible to see boost between 15-45 psi...it was either all in or not.

After installing the boost tee as plumbed above...I dialed it in (unknowingly but suspecting a leak), and found that now transient response was down some, but I could at least operate in the 15-45psi range. I was disappointed in Boost vs BP ratios though.

Just got the new TS Diesel Tee in that has 1/4" barbed fittings...and it's an all new truck all over again. Better transient response, and BP vs Boost is much more favorable than previous. I know some might be looking at this post crosseyed like I'm crazy...but I'm adamant that boost leaks will make or break your setup...and drive you in circles chasing "other stuff" in attempt to fix 'em.

A slight sidetrack to the OPs original question in the thread...I've read on other platforms, specifically the 6.4 fellas are seeing WG diaphragm failures..presumably from excessive pressures/heat. Is this a point worthy to consider when deciding how to spring/plumb your gate(s)?

PSJs setup could in theory expose the top of the WG diaphragm to the maximum boost pressure his turbo could generate...which could be 40-50 psi (PSJ I'm not sharpshooting your setup at all, just listed it as an example my question...as I'm here to learn too)....where as the other extreme is a scenario like the one I listed above...where the bottom of the WG diaphragm is exposed to a minimal amount of boost...ie..the controller decides how much boost the WG sees to assist in opening it. Kind of leads into the question I posted for HRT above...this balanced deal he mentions...my feeble mind can't grasp it though.