You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Search results

-

A

FFD Rail System

I started with a search for Sturman Industries on Google and that led me to the Caterpillar lawsuit and a few patents. With those patents I just used the cited patents listed and branched out pretty rapidly. You might find patent US5454359A to be interesting. Navistar engineers developed a...- andharri

- Post #127

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

Well I did about 2 hours worth of digging. No doubt did not cover everything but did manage to find a few interesting pieces of information. The first patent I came across was US5806494A which describes the integrated oil rail system and injector system. In the second paragraph of the...- andharri

- Post #125

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

Actually, as argued earlier in this thread part of this discussion is based around whether the FFD rails would actually deliver more oil to the injector or result in a sustained ICP reading without delivering more oil. In the former situation a problem is solved, in the later the problem is...- andharri

- Post #120

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

If you can find them it'd thrill me to read them. I agree on oversized for distribution, though how much I don't know, and truthfully I'd rather have it oversized than undersized! Like we've never had to deal with that kind of problem before... For oil rail design rationale I was leaning more...- andharri

- Post #110

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

I'm not sure how to do the fancy quotes of individual parts of a post.... darn. I'll play around with that later. Anyways, I'm not sure about the rails being used for harmonic dampening specifically, would be very interesting if that is the case, I'd like to see the paper written on that...- andharri

- Post #108

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

I've thought about the theory 1 you've listed as well. At 3000 psi generic motor oil will compress about 1% of original volume (more if its aerated). Less volume would be easier to compress but the problem still remains that the only volume that needs to be compressed is what is lost through...- andharri

- Post #104

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

It's essentially "free flowing" until the poppet closes or the plunger completely depresses preventing volume change and flow.- andharri

- Post #66

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

When its closed, assuming all injectors are closed at the same time (and there are 8 of them), the whole HPO system has the same pressure because the volume isn't changing and there's no flow (closed system). No flow = no pressure change. Uninteresting situation and not useful for injection...- andharri

- Post #61

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

All i'm saying is the bucket you're trying to fill is the injector, not the log. You'd need to add your rock there to have that effect. The volume of oil that the pump is filling is in the injector, not the log. The log is already full. EDIT: The hose doesn't create the need, but it can...- andharri

- Post #50

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

If you aren't "pouring anything out" and its a "constant pressurized chamber" then the pressure is constant throughout the filled volume. That's how hydraulics work with no flow.- andharri

- Post #44

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

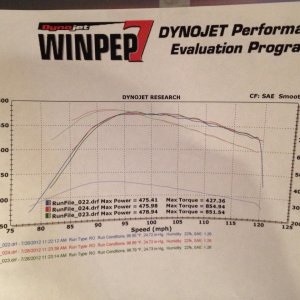

The volume change may not be enough to hinder, but the concept is just counter to what is described by general fluid dynamics. I'm in for some data, like someone mentioned earlier, before and after dyno runs with the product would tell the story.- andharri

- Post #43

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

Correct, but that is the period in which the interesting things are happening correct? Plunger moves down, volume of oil cavity increases, fuel is pressurized and exits the injector, power is made. Valve closes, plunger moves back into position and oil is expelled so that the process can...- andharri

- Post #40

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

You are right that equation is for a steady state system and any real system is dynamic, like the operation of an engine. However, the ways in which pressure, radius, and volumetric flow rate are related are all described from the general Navier-Stokes relation, from which Hagen-Poiseuille...- andharri

- Post #39

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

Exactly, I like your explanation. I was going to repost a similar one but you beat me to it!- andharri

- Post #36

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

Actually, you should be removing the oil. The oil exits out of the injectors when the poppet valve reseats and the fuel pressure returns the pistons to their original positions. Oil volume is constantly being removed.- andharri

- Post #35

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

Agreed, the pressure should be more easily sustainable with less volume to manage. However, from what I've heard regarding the ability to adequately feed the HEUI injectors the volume of oil is more in demand than the pressure. Isn't this why hybrid injectors have become so popular and...- andharri

- Post #25

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

Oh no there's certainly a pressure drop. It's just less of pressure drop compared to a smaller diameter region, or design. And it's not really what I think just what the equations say it should be. Given the length of the system in question (relatively short) and the typical pressures that...- andharri

- Post #24

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

Going further with the fire hose analogy, the reason the firemen use a hose larger than a garden hose is specifically because it will provide more volume of water.- andharri

- Post #18

- Forum: 7.3 Aftermarket

-

A

FFD Rail System

The general equation describing fluid dynamics of this nature is the Hagen-Poiseuille (HP) equation: dP = 8uLQ/(pi * R^4) where dP is the pressure difference over the length of the system L, u is the dynamic viscosity (intrinsic to the oil), Q is the volumetric flow rate, and R is the pipe...- andharri

- Post #15

- Forum: 7.3 Aftermarket