SkySki Jason

New member

I thought I'd introduce myself here. Hi, my name is Jason and I'm addicted to PSD's and WVO. I got hooked on PSD in 2003 when I got my '01 F350 and learned about TheDieselStop, then in 2005 I started gathering oil and parts to convert it to WVO. I've often said I can stop anytime I want - but I don't know if I really could. Is there any help for me????

My F350 has a Vegistroke-style DIY conversion with over 140k miles since conversion. Current configuration uses a Frybrid heated pick-up, alum TIH, FASS HPFP, coolant-heated filter, more TIH, a 16plate FPHE on firewall and I have an aux coolant pump in the VO loop to maintain good coolant flow. I see 180*+ VO before the heads. The system is deadheaded and VO is fed into the 'test ports' in the heads. There is a 12v solenoid valve that allows fast purging of the VO from the heads. I used PTFE-lined SS braided fuel lines with JIC ends on the engine.

Here's some of the plumbing on the new engine:

I built the Excursion for my (ex)wife and wanted it to be simple and BULLETPROOF. I bought a Vegistroke V3 module from Frybrid, mostly because CG was willing to build an under-body VO tank and I was working in Seattle at the time. So, Frybrid heated pick-up in a 38gal tank, TIH, V3 module (coolant heated, FASS, air bleed, pre-pump filter, primary VO filter, temp and press switches, purge solenoid, VO check valve, etc), more TIH a 16plate FPHE on firewall and aux coolant pump. There is NO RUBBER FUEL HOSE anywhere in this system, its either alum tubing or PTFE-lined SS braided hose (on engine). Also sees 180*+ VO before the heads! The truck has over 90k miles on the high-cholesterol diet now.

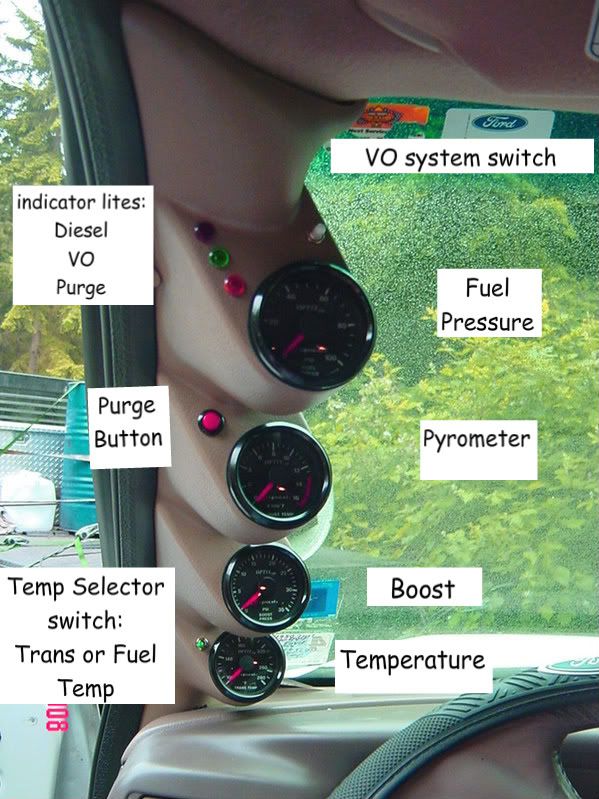

Gauges and VO system controls:

VO tank during construction:

'Stealthy' VO tank filler:

FPHE:

V3 during mock-up:

The only mods to the factory fuel systems are the addition of check valves at the heads and the ability to turn off the OE fuel pump.

I ended up with a cracked piston at 308k miles and just shy of 120k on grease in the F350. There was no sign of 'alternative fuels' in the broken engine, except maybe some extra carbon in ringland (could also be attributed to idling on diesel...). This engine towed 10-15k lb trailers more than 50% of its life and had a chip for over 100k and 175/146 SS's for the last 70k.

My primary filtration method has been heat and settle using 110-120* and settle for 48+ Hrs, drain bottom and test for water. When its 'dry', I pump thru 10 mic and 2 mic (absolute) FUEL FILTERS and into the trucks. I get 10-15k miles or more out of on-board VO filters. Now, I have a gravity-fed CF but still use a filter before the trucks for good measure.

My F350 has a Vegistroke-style DIY conversion with over 140k miles since conversion. Current configuration uses a Frybrid heated pick-up, alum TIH, FASS HPFP, coolant-heated filter, more TIH, a 16plate FPHE on firewall and I have an aux coolant pump in the VO loop to maintain good coolant flow. I see 180*+ VO before the heads. The system is deadheaded and VO is fed into the 'test ports' in the heads. There is a 12v solenoid valve that allows fast purging of the VO from the heads. I used PTFE-lined SS braided fuel lines with JIC ends on the engine.

Here's some of the plumbing on the new engine:

I built the Excursion for my (ex)wife and wanted it to be simple and BULLETPROOF. I bought a Vegistroke V3 module from Frybrid, mostly because CG was willing to build an under-body VO tank and I was working in Seattle at the time. So, Frybrid heated pick-up in a 38gal tank, TIH, V3 module (coolant heated, FASS, air bleed, pre-pump filter, primary VO filter, temp and press switches, purge solenoid, VO check valve, etc), more TIH a 16plate FPHE on firewall and aux coolant pump. There is NO RUBBER FUEL HOSE anywhere in this system, its either alum tubing or PTFE-lined SS braided hose (on engine). Also sees 180*+ VO before the heads! The truck has over 90k miles on the high-cholesterol diet now.

Gauges and VO system controls:

VO tank during construction:

'Stealthy' VO tank filler:

FPHE:

V3 during mock-up:

The only mods to the factory fuel systems are the addition of check valves at the heads and the ability to turn off the OE fuel pump.

I ended up with a cracked piston at 308k miles and just shy of 120k on grease in the F350. There was no sign of 'alternative fuels' in the broken engine, except maybe some extra carbon in ringland (could also be attributed to idling on diesel...). This engine towed 10-15k lb trailers more than 50% of its life and had a chip for over 100k and 175/146 SS's for the last 70k.

My primary filtration method has been heat and settle using 110-120* and settle for 48+ Hrs, drain bottom and test for water. When its 'dry', I pump thru 10 mic and 2 mic (absolute) FUEL FILTERS and into the trucks. I get 10-15k miles or more out of on-board VO filters. Now, I have a gravity-fed CF but still use a filter before the trucks for good measure.