You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.0 Starting Issue

- Thread starter GRN250

- Start date

GRN250

Member

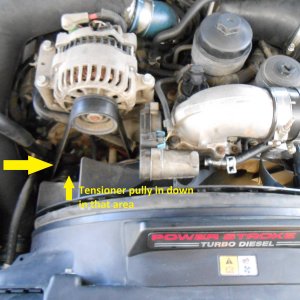

The sensor mounting surface was relatively clean. I wiped it down good and made sure to seat the sensor when installing it.

Last edited:

Troubleshooting CMP: first check the sensor connector for oil - a broken o-ring can cause an oil leak into the electrical connector.

To check the sensor: You can check the red wire (pin 31 ) and the orange wire (at pin 43) at the PCM center connector (C1381c). Using a multimeter that reads hertz check across both wires while cranking, you should see around 1.3 Hz (between 1.1 and 1.9 Hz is acceptable). The operating range of the sensor is 0.5 to 50 Hz.

Testing the sensor AND the wiring: Measure the resistance between the PCM engine connector C1381c (center plug) pin 31, harness side and the same PCM engine connector pin 43, harness side. Should be between 800 and 1000 ohms (sensor AND wiring resistance).

To check the WIRING ONLY: You can measure the resistance between the PCM engine connector (C1381c) pin 31, harness side and the CMP sensor pin 1, harness side; and between the PCM engine connector pin 43, harness side and the CMP sensor pin 2, harness side. Resistance on each test should be less than 5 ohms according to the manual, but in reality should be below 0.5 ohms. CMP connector is C1275.

To check the sensor: You can check the red wire (pin 31 ) and the orange wire (at pin 43) at the PCM center connector (C1381c). Using a multimeter that reads hertz check across both wires while cranking, you should see around 1.3 Hz (between 1.1 and 1.9 Hz is acceptable). The operating range of the sensor is 0.5 to 50 Hz.

Testing the sensor AND the wiring: Measure the resistance between the PCM engine connector C1381c (center plug) pin 31, harness side and the same PCM engine connector pin 43, harness side. Should be between 800 and 1000 ohms (sensor AND wiring resistance).

To check the WIRING ONLY: You can measure the resistance between the PCM engine connector (C1381c) pin 31, harness side and the CMP sensor pin 1, harness side; and between the PCM engine connector pin 43, harness side and the CMP sensor pin 2, harness side. Resistance on each test should be less than 5 ohms according to the manual, but in reality should be below 0.5 ohms. CMP connector is C1275.

GRN250

Member

The resistance between pins 31 and 43 is 810 ohms. I will have to get some angled, small meter leads to check the frequency across the pins. Thanks for your helpTroubleshooting CMP: first check the sensor connector for oil - a broken o-ring can cause an oil leak into the electrical connector.

To check the sensor: You can check the red wire (pin 31 ) and the orange wire (at pin 43) at the PCM center connector (C1381c). Using a multimeter that reads hertz check across both wires while cranking, you should see around 1.3 Hz (between 1.1 and 1.9 Hz is acceptable). The operating range of the sensor is 0.5 to 50 Hz.

Testing the sensor AND the wiring: Measure the resistance between the PCM engine connector C1381c (center plug) pin 31, harness side and the same PCM engine connector pin 43, harness side. Should be between 800 and 1000 ohms (sensor AND wiring resistance).

To check the WIRING ONLY: You can measure the resistance between the PCM engine connector (C1381c) pin 31, harness side and the CMP sensor pin 1, harness side; and between the PCM engine connector pin 43, harness side and the CMP sensor pin 2, harness side. Resistance on each test should be less than 5 ohms according to the manual, but in reality should be below 0.5 ohms. CMP connector is C1275.