wint

New member

Needing the function of traction bars but not wanting to pay for the kits available I decided to build my own.

My parts list consisted of:

10ft stick of 1.5in sch 40 tubing

1/4in and 3/8in plate steel

(2) Category 1, tractor top links

(4) Top link pins

(8) 3/8s bolts

I started by cutting down my pipe to 2 5ft lengths. I then cut my top links in half. The top links had a slightly larger OD than the pipes ID. So after grinding the top links down to a tight, taper fit into the pipe, I beat the top links in 2.5in.

Then welded them in.

A coat of paint and they were good to go.

Next was the axle mounts. I started with laying under the truck and coming up with a design template.

Then proceeded transfer the idea to metal.

Plasma cutter makes quick work of these!

I then popped a 3/4in hole into each of them.

Figured out my placement and spacing and welded them on.

Next task was to figure out a front mount. I looked around on the frame for a suitable mounting point. I found 4 holes placed in line with the transfercase. After figuring out the drilling pattern I put the holes into the 3/8s plate. Then drilled another 3/4in hole. Using the top link pins I welded them in as studs.

For extra strength i opened a hole in some 1/4 plate and plug welded the back of the stud to it.

I have them finished but dont have any pictures due to it being dark. I will be sure to post some tomorrow though!

My parts list consisted of:

10ft stick of 1.5in sch 40 tubing

1/4in and 3/8in plate steel

(2) Category 1, tractor top links

(4) Top link pins

(8) 3/8s bolts

I started by cutting down my pipe to 2 5ft lengths. I then cut my top links in half. The top links had a slightly larger OD than the pipes ID. So after grinding the top links down to a tight, taper fit into the pipe, I beat the top links in 2.5in.

Then welded them in.

A coat of paint and they were good to go.

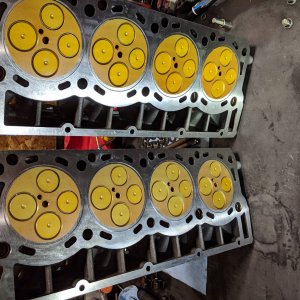

Next was the axle mounts. I started with laying under the truck and coming up with a design template.

Then proceeded transfer the idea to metal.

Plasma cutter makes quick work of these!

I then popped a 3/4in hole into each of them.

Figured out my placement and spacing and welded them on.

Next task was to figure out a front mount. I looked around on the frame for a suitable mounting point. I found 4 holes placed in line with the transfercase. After figuring out the drilling pattern I put the holes into the 3/8s plate. Then drilled another 3/4in hole. Using the top link pins I welded them in as studs.

For extra strength i opened a hole in some 1/4 plate and plug welded the back of the stud to it.

I have them finished but dont have any pictures due to it being dark. I will be sure to post some tomorrow though!