John@Outlaw_Diesel

New member

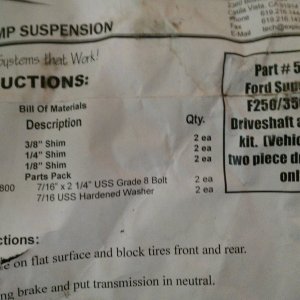

I have two different sets of traction bars on my old obs and my Superduty, never had a problem with the tractor links, plenty of boosted lanunches, sledpulling, etc. Love the setup Wint. Like the idea that you can take them off in a matter of seconds.