Thanks. There were some benefits to doing research into the various systems the gas and alcohol guys use. There surge tanks are much more popular. The pencil to napkin flow diagram in that thread explains it.

One of the parts I really like is running the return line back thru the surge tank. It mixes with the other fuel keeping a more consistent temp but more so it adds flow volume to the surge tank for the high pressure fuel pump to have access to. WE actually use only a small % of the fuel we run thru the fuel rails in the heads. 90% end up back in the tank. This then is added to the fuel available to the pump itself. So even if you were one a severe angle where the tank PU is uncovered you would have a good deal of fuel before your pump inlet was uncovered. The surge tank does nto pressurize as the return lines flow thru it. That means the lift pump is working as atmosphere thru its free flowing which puts it at its max flow rate with the least strain on the pump system.

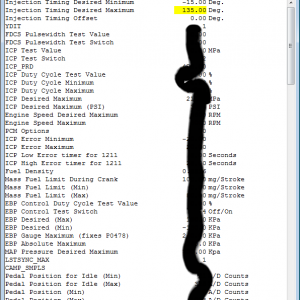

Having a inline fuel cooler also is nice since our fuel runs thru the heads which is some of the hots areas in the engine. I have thought of putting a bypass line with some valves for very cold winter days. Think how many times the fuel cycles thru the heads when you are at 1/4 tank using a 100 gph fuel pump. That can get your fuel hot hot hot. That decreases its lubricity protections. I know I posted it after I looked it up somewhere but IIRC ideal diesel fuel temp is suppose to below 100 F maybe in the 70s. Can not recall for sure but it makes sense. As fuel heats up it expands. As we inejct based on volume this means less BTUs or actual fuel density is getting into the cylinder. The more we can stabilize fuel temp IMO the better. Not to mention our fuel is what lubes the injectors.

What I want to see, if I can get it to fit, is putting the surge tank, HP filter, and dahl into the OEM battery locations. I will leave the lift pump on the rail close to the tank. I can use both sides so no big deal just need to ensure I have the height for them That damn dahl is huge but its performance is so good. It also allows for a heater if I wanted to add one.

AS this is an Excursion the dual battery case actually fits perfectly where the spare tire use to sit over the left rear axle. Put grounds to the frame.