MT_Diesel

New member

Hi guys, I’m looking for ideas or suggestions of what to test and/or fittings to check to help the local dealership fix my truck since they can’t seem to figure it out and I’ve been without the truck for 7 weeks now. This seems to be a real head scratcher for RCD as well as the local dealer. I’m hoping someone has run into the same/similar problem and been able to fix it. I know there are a lot of 6.4 experts here on PSA. Thanks for any help you can provide!

The Problem:

Truck is getting air in the fuel somehow and randomly dies. When it runs it is running smoothly like there are no issues, then spontaneously dies (due to airlock in the fuel according to dealership). The dealership says it is only affecting the left bank – not sure how they know this, perhaps diagnostics – which is the same side I just replaced 2 injectors on. Dealership and RCD suspect air in the fuel likely caused the failure of the injectors in the first place. Truck won’t run long enough to get to operating temp.

Fuel System Mods (all done ~7k miles ago):

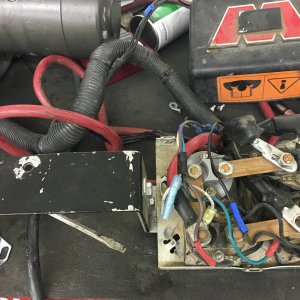

FASS 150 LPFP

Diesel Dr. Duel Fueler kit

2 new HPFPs with ~7k miles – one locked up shortly after duel kit was added and was replaced with a new one

Elite fuel bowl delete

Ported fuel rails

Six 60% injectors from orginal build ~7k miles

Two new 60% injectors – 18 miles

Stock fuel cooler

Background:

I purchased a 2008 F350 in March. The truck was built by River City Diesel and was local to them so I had them do a pre-buy inspection and they gave it a clean bill of health. I drove it almost 2k miles home and put another 500 miles on it over 3 weeks when I got home. Truck ran great. I only mention this because I believe all was working normal when I purchased it. From the little I know it wouldn’t have made it 2500 miles with an air in fuel problem. I did retune it from the custom (to this truck) RCD 485 to custom RCD 525 a week or two before the first problem. Anyway, I went out to start it one day and it idled really rough when it kicked into the high idle. No performance diesel shops local to me so I had it towed to the local dealer.

Diagnosis showed 1 hung injector and another possibly bad injector - both on the left bank (60% injectors with 7k miles total on them). Dealership pulled the 4 left bank injectors and sent them to RCD for testing. 2 of them were bad as the dealership suspected. RCD sent the 2 good injectors plus 2 new Alliant 60% injectors with new fuel lines for all. Dealership reinstalled the injectors and I got the truck back. I drove it a total of 18 miles before it died on the side of the interstate (just a short 3 mile in-town stretch). Truck would not start so back to the dealership. Truck had seemed to be running just fine though I do remember thinking the rail pressure at idle (in gear) was a little high and moving around a little more than usual. But I've only driven the truck for 3 weeks so I don't know it that well. Also of note, when the truck died (in a downpour no less) I noticed that the bolts holding the flange between the two turbos were missing and there was a visible gap between flanges. Dealership said that is not related to the work they did and that it needs a new gasket & bolts and of course the cab has to come off for that (according to them). Suck. Perhaps I’ll do that myself cab on if it’s not too difficult.

Dealership said air locked fuel system caused it to die. They said it is getting air in the fuel and appears to only be affecting the left bank. RCD recommended they drop the tank to perform a test on that – not sure whether a pressure test or other test. Dealership didn’t do that but hooked up a clear tube at/near the fuel cooler and cycled the LPFP to see if motor was getting aerated fuel. They said the fuel was not aerated – pure fuel. They said when it is aerated you can see bubbles and foam. The dealership techs are completely clueless when it comes to the modified components and are relying on RCD for tech support. RCD has been awesome continuing to help me/them out.

To me it seems like air would have to be getting in the suction part of the fuel system. I would think any leaks from the LPFP to the injectors would show up as fuel leaking out, not air getting in. Would there be any value in pressure testing the tank or visually inspecting the pickup in the tank? Or could air be getting in at the LPFP? Are there any other tests that can be done to check for aeration in the low pressure or high pressure portions of the system?

I’m going to call around to the nearest performance diesel shops – minimum 2 hrs away – to see about trailering it to one of them if the dealership can’t make any progress in the near future. But I wanted to solicit help from the PSA brain trust before I haul it out of town.

Thanks again for any help you can provide!

The Problem:

Truck is getting air in the fuel somehow and randomly dies. When it runs it is running smoothly like there are no issues, then spontaneously dies (due to airlock in the fuel according to dealership). The dealership says it is only affecting the left bank – not sure how they know this, perhaps diagnostics – which is the same side I just replaced 2 injectors on. Dealership and RCD suspect air in the fuel likely caused the failure of the injectors in the first place. Truck won’t run long enough to get to operating temp.

Fuel System Mods (all done ~7k miles ago):

FASS 150 LPFP

Diesel Dr. Duel Fueler kit

2 new HPFPs with ~7k miles – one locked up shortly after duel kit was added and was replaced with a new one

Elite fuel bowl delete

Ported fuel rails

Six 60% injectors from orginal build ~7k miles

Two new 60% injectors – 18 miles

Stock fuel cooler

Background:

I purchased a 2008 F350 in March. The truck was built by River City Diesel and was local to them so I had them do a pre-buy inspection and they gave it a clean bill of health. I drove it almost 2k miles home and put another 500 miles on it over 3 weeks when I got home. Truck ran great. I only mention this because I believe all was working normal when I purchased it. From the little I know it wouldn’t have made it 2500 miles with an air in fuel problem. I did retune it from the custom (to this truck) RCD 485 to custom RCD 525 a week or two before the first problem. Anyway, I went out to start it one day and it idled really rough when it kicked into the high idle. No performance diesel shops local to me so I had it towed to the local dealer.

Diagnosis showed 1 hung injector and another possibly bad injector - both on the left bank (60% injectors with 7k miles total on them). Dealership pulled the 4 left bank injectors and sent them to RCD for testing. 2 of them were bad as the dealership suspected. RCD sent the 2 good injectors plus 2 new Alliant 60% injectors with new fuel lines for all. Dealership reinstalled the injectors and I got the truck back. I drove it a total of 18 miles before it died on the side of the interstate (just a short 3 mile in-town stretch). Truck would not start so back to the dealership. Truck had seemed to be running just fine though I do remember thinking the rail pressure at idle (in gear) was a little high and moving around a little more than usual. But I've only driven the truck for 3 weeks so I don't know it that well. Also of note, when the truck died (in a downpour no less) I noticed that the bolts holding the flange between the two turbos were missing and there was a visible gap between flanges. Dealership said that is not related to the work they did and that it needs a new gasket & bolts and of course the cab has to come off for that (according to them). Suck. Perhaps I’ll do that myself cab on if it’s not too difficult.

Dealership said air locked fuel system caused it to die. They said it is getting air in the fuel and appears to only be affecting the left bank. RCD recommended they drop the tank to perform a test on that – not sure whether a pressure test or other test. Dealership didn’t do that but hooked up a clear tube at/near the fuel cooler and cycled the LPFP to see if motor was getting aerated fuel. They said the fuel was not aerated – pure fuel. They said when it is aerated you can see bubbles and foam. The dealership techs are completely clueless when it comes to the modified components and are relying on RCD for tech support. RCD has been awesome continuing to help me/them out.

To me it seems like air would have to be getting in the suction part of the fuel system. I would think any leaks from the LPFP to the injectors would show up as fuel leaking out, not air getting in. Would there be any value in pressure testing the tank or visually inspecting the pickup in the tank? Or could air be getting in at the LPFP? Are there any other tests that can be done to check for aeration in the low pressure or high pressure portions of the system?

I’m going to call around to the nearest performance diesel shops – minimum 2 hrs away – to see about trailering it to one of them if the dealership can’t make any progress in the near future. But I wanted to solicit help from the PSA brain trust before I haul it out of town.

Thanks again for any help you can provide!