windrunner408

New member

- Joined

- Jul 27, 2011

- Messages

- 1,496

- Reaction score

- 0

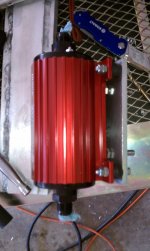

So while I was at the Dyno event on Saturday and Bill was driving my truck, I was able to monitor my fuel pressure during the WOT runs Bill was doing and noticed that it was dropping from ~64psi at idle to about 50psi in the WOT runs on the dyno. I know that 50psi is still ok for the injectors but I was hoping that with the AD150, fuel sump, AND RR kit that I would be able to hold closer to 60psi at the regulator. So since I have roughly 90k miles on the stocker, I decided to retire it and give the fuel system (hopefully) its last major upgrade that it will ever need (even if I do go with larger injectors later). The setup incorporates the venerable A1000 fuel pump, AD150, RR kit, and XDP Fuel sump. I pulled ALL of the fuel lines (with the exception of the return line that goes from the OEM pump to the tank) and replaced them with new Aeroquip Socket less AN lines. I am running 10AN line from the sump all the way to the AD150 and from it to the A1000, 8AN line from the A1000 to the y-block, and the 6AN line currently in use for feeding the heads will still be retained. The return line is 6AN line from the regulator to where it connects to the factory 5/16” return line. I fabricated a bracket out of 1/4in aluminum plate that I had to mount the pump in the factory location. All hardware is stainless steel and I used some rubber grommets as isolators for the pump to help with vibrations/shocks to the pump from the frame.

I received everything from Summit Racing on Wednesday, started working Thursday evening, and got everything installed and buttoned up yesterday morning. I already had the fuel bowl deleted when I bought the AD150 and new lines that I tied into the factory supply and return for sending fuel via 90* fittings directly to the front of the heads and to the Strictly Diesel RR kit that comes off the back of the heads. I will update the thread after the install, periodically as I drive the truck to speak to the longevity of the system, and what the fuel pressure does when I either stick the truck back on the dyno or take it to the track.

The final build list for my fuel system is as follows with parts in order from tank to motor:

XDP Sump

1/2" male NPT to 5/8" barbed hose fitting

~5ft of Aeroquip Socketless 10AN hose

Aeroquip 10AN Socketless hose end

Aeroquip 10AN to 3/8" NPT fitting

AD150

Aeroquip 10AN to 3/8" NPT fitting

Aeroquip 10AN Socketless hose end

~3ft of Aeroquip Socketless 10AN hose

Aeroquip 10AN Socketless hose end

Aeromotive 10AN male to 10 ORB fitting

Aeromotive A1000

Aeromotive 8AN male to 10 ORB

Aeroquip 8AN Socketless hose end

~6ft of Aeroquip Sockless 8AN hose

Aeroquip 8AN Socketless hose end

Aeroquip 8AN male to 8AN male coupler with gauge port

Aeroquip 8AN female to 8AN female coupler

Summit Racing 8AN inlet to 6AN outlets Y-block

Summit Racing 6AN hose ends

Summit Racing 6AN stainless steel braided hose

Summit Racing 6AN hose ends

Earl’s Racing 6AN male to M12x1.5mm 90* fittings

Strictly Diesel RR banjos and lines

Fuelab Regulator

Summit Racing 6AN hose end

Summit Racing 6AN stainless steel braided hose

Summit Racing 6AN hose end

Summit Racing 6AN male to 6AN male coupler

Aeroquip 6AN Socketless hose end

~6ft of Aeroquip Socketless 6AN hose

Aeroquip 6AN Socketless hose end

Russell 6AN to 5/16" Fuel Rail Adapter

Factory 5/16” fuel line to the tank

For wiring everything up I used a Summit Racing 30 Amp Fuel Pump Relay kit. It has 12ga wiring going from the relay to the pump and ga wiring for connecting the relay to the battery. There isnt really a fuse but rather an automatic resetting of a 30 Amp circruit breaker. I only used the hot wire from the OEM fuel pump harness for the "Switched 12v" source and I just connected the negative end of the A1000 to the ground wire in the OEM fuel pump harness. I was wondering if maybe I should just get some 12ga wire for the ground of the pump and run it all the way to the battery. Any thoughts?? The main thing I did notice is that you can hear the A1000 below the floor boards when it is running and the truck is running. I also backed the fuel pressure back down to 65psi so hopefully it says there.

Hopefully this thread will give some folks that have been debating building their own system fuel system some ideas they can use for their own or if at the very least know and learn what not to do. LOL LOL LOL

Pics will flow from sump to motor. Sorry if some of the pics are a little too close as it was difficult getting detail and showing the whole system with out other components on the truck getting in the way. The last pic is how the pump looks if you just peak your head under the body of the truck,

I received everything from Summit Racing on Wednesday, started working Thursday evening, and got everything installed and buttoned up yesterday morning. I already had the fuel bowl deleted when I bought the AD150 and new lines that I tied into the factory supply and return for sending fuel via 90* fittings directly to the front of the heads and to the Strictly Diesel RR kit that comes off the back of the heads. I will update the thread after the install, periodically as I drive the truck to speak to the longevity of the system, and what the fuel pressure does when I either stick the truck back on the dyno or take it to the track.

The final build list for my fuel system is as follows with parts in order from tank to motor:

XDP Sump

1/2" male NPT to 5/8" barbed hose fitting

~5ft of Aeroquip Socketless 10AN hose

Aeroquip 10AN Socketless hose end

Aeroquip 10AN to 3/8" NPT fitting

AD150

Aeroquip 10AN to 3/8" NPT fitting

Aeroquip 10AN Socketless hose end

~3ft of Aeroquip Socketless 10AN hose

Aeroquip 10AN Socketless hose end

Aeromotive 10AN male to 10 ORB fitting

Aeromotive A1000

Aeromotive 8AN male to 10 ORB

Aeroquip 8AN Socketless hose end

~6ft of Aeroquip Sockless 8AN hose

Aeroquip 8AN Socketless hose end

Aeroquip 8AN male to 8AN male coupler with gauge port

Aeroquip 8AN female to 8AN female coupler

Summit Racing 8AN inlet to 6AN outlets Y-block

Summit Racing 6AN hose ends

Summit Racing 6AN stainless steel braided hose

Summit Racing 6AN hose ends

Earl’s Racing 6AN male to M12x1.5mm 90* fittings

Strictly Diesel RR banjos and lines

Fuelab Regulator

Summit Racing 6AN hose end

Summit Racing 6AN stainless steel braided hose

Summit Racing 6AN hose end

Summit Racing 6AN male to 6AN male coupler

Aeroquip 6AN Socketless hose end

~6ft of Aeroquip Socketless 6AN hose

Aeroquip 6AN Socketless hose end

Russell 6AN to 5/16" Fuel Rail Adapter

Factory 5/16” fuel line to the tank

For wiring everything up I used a Summit Racing 30 Amp Fuel Pump Relay kit. It has 12ga wiring going from the relay to the pump and ga wiring for connecting the relay to the battery. There isnt really a fuse but rather an automatic resetting of a 30 Amp circruit breaker. I only used the hot wire from the OEM fuel pump harness for the "Switched 12v" source and I just connected the negative end of the A1000 to the ground wire in the OEM fuel pump harness. I was wondering if maybe I should just get some 12ga wire for the ground of the pump and run it all the way to the battery. Any thoughts?? The main thing I did notice is that you can hear the A1000 below the floor boards when it is running and the truck is running. I also backed the fuel pressure back down to 65psi so hopefully it says there.

Hopefully this thread will give some folks that have been debating building their own system fuel system some ideas they can use for their own or if at the very least know and learn what not to do. LOL LOL LOL

Pics will flow from sump to motor. Sorry if some of the pics are a little too close as it was difficult getting detail and showing the whole system with out other components on the truck getting in the way. The last pic is how the pump looks if you just peak your head under the body of the truck,

Attachments

Last edited: