BlueOx

New member

- Joined

- Nov 2, 2012

- Messages

- 1,045

- Reaction score

- 0

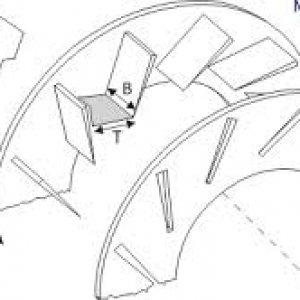

Ok I'm wanting to install some 2x2 flush mount lights in my rear bumper. Anybody have any tips or tricks for cutting the holes in the bumper? I wanna make sure I do this right the first time lol

Sent from the wild blue yonder....

Sent from the wild blue yonder....