jschildm

Member

Back story ... For the last few months my speedometer would bounce around sometimes when I hit a bump. After some brief searching online it sounded like the wiring down to the speed sensor on the rear axle was the likely culprit, especially since it seemed like it happened when the rear tires hit a bump.

A couple weekends ago I messed with it briefly looking for obvious spots of damage. I didn't have a lot of time, and didn't have any luck, but after driving it the speedometer was jumping around a lot more often, so I figured I was on the right track.

The fun part ... Last weekend I did a more thorough inspection and found a splice in the wires near the connector to the sensor and figured I had found my problem. I replaced the existing splice and took a trip around the block to try it out. The speedometer now doesn't move off of zero ... well great!

I purchased a new speed sensor (cheap one from O'Reilly's) and that didn't do the trick. I put a new connector on it that connects to the speed sensor, and more of the same.

Last night I used a volt meter to detect the frequency from the sensor. I believe I am getting a signal from the sensor itself, and also through the connector I added. I have a couple questions ... does it matter which wire goes to which pole on the sensor? I think I am going to replace the wires in the harness and see what that does. The wires down by the axle were black and nasty. Any other methods for troubleshooting, or ideas I am missing?

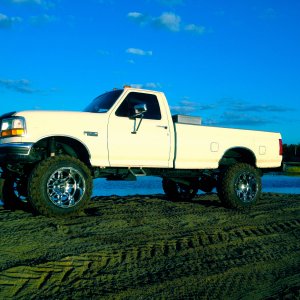

Sorry for the long post. One last question ... what is this orange cord/plug in the picture?

A couple weekends ago I messed with it briefly looking for obvious spots of damage. I didn't have a lot of time, and didn't have any luck, but after driving it the speedometer was jumping around a lot more often, so I figured I was on the right track.

The fun part ... Last weekend I did a more thorough inspection and found a splice in the wires near the connector to the sensor and figured I had found my problem. I replaced the existing splice and took a trip around the block to try it out. The speedometer now doesn't move off of zero ... well great!

I purchased a new speed sensor (cheap one from O'Reilly's) and that didn't do the trick. I put a new connector on it that connects to the speed sensor, and more of the same.

Last night I used a volt meter to detect the frequency from the sensor. I believe I am getting a signal from the sensor itself, and also through the connector I added. I have a couple questions ... does it matter which wire goes to which pole on the sensor? I think I am going to replace the wires in the harness and see what that does. The wires down by the axle were black and nasty. Any other methods for troubleshooting, or ideas I am missing?

Sorry for the long post. One last question ... what is this orange cord/plug in the picture?