kyle43335

In the Brig (Banned)

- Joined

- May 18, 2011

- Messages

- 2,364

- Reaction score

- 0

Thats what I was getting at, you need to shim the spring in this instance right, or at least once you have taken enough off I would think it would be worth it.

Regardless though, I'll be able to measure protrusion tomorrow and I believe thats where our contact issue lies. The compression issue was the valve and the contact issue being the deck was ground by the pistons were not.

more tomorrow!

your not taking enough material off to really affect seat pressure to the point,causing your issue.

where this senario would be valid,is at wot. boost and drive pressure overcoming seat pressure blowing the valves open.

check this out once.

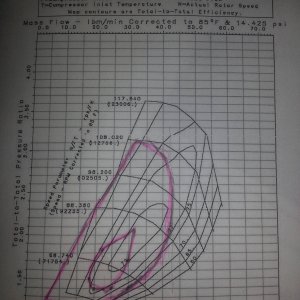

piston protrusion is around .030

a oem gasket has a installed height of around .052

some of the bo gaskets ive measured back in the day were .010 or better thinner than stock(oem)

pp .030

+ .010 deck the block(this would be a estimate. could be more)

--------

.040 piston above deck

.042 this is per layer measurement. (uninstalled height) gasket compresses roughly .008 thou.

just doing the math with the bo gasket uninstalled,you have .002 thou remaining.

if you take the rough .008 that the gasket will compress? that drops you to no clearance.

the pistons still have the identifying words and size in the face,indicating that they didnt have any material removed to compensate for the block decking.

Last edited: