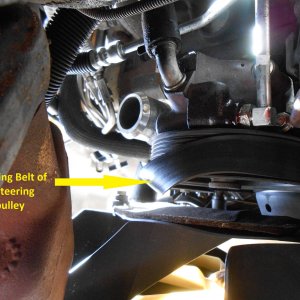

So you are saying I should fire a seperate relay for each pump. I am assuming the little cube relays that are used for everything else.

Yes, I would use a relay for each pump. You can use the factory harness to operate both relays though. Yes, I'm talking about the little cube relays.

I say to use a relay for each pump because one pump might lock up and it could heat up the relay because it will start to pull more amps. If this happens, you would lose both pumps if the relay fails. If you have a relay on each pump, this would not happen.

See the link below for the type of relays I'm talking about.

You can also take a look at www.bcae1.com website, it has a lot of good 12V electrical information. There are sub forums for specific items such as relays, switches and etc..

40A Relay