a_moore

Active member

^

|

Mine is the same as Moores setup in avatar.

My avatar is yours Seth.....I was in to big a hurry to install mine there were no pictures. lol

^

|

Mine is the same as Moores setup in avatar.

My avatar is yours Seth.....I was in to big a hurry to install mine there were no pictures. lol

I didn't build this like some of the builder/drivers on this thread...but thought Jake's work on this kit might be worthy of review.

Up pipes/intermediate pipe ceramic coated

IC pipes powdercoated

Mishimoto 6.0 IC (bolted right in)

Tried to get some closeups of the oil supply/return lines he uses, as well as his craftsmanship on the Wastegate/downpipe/plumbing.

Have seen 50+ psi with 350/200s on tune #5 of #6 before I back out. Haven't got a data log to post with drive pressure vs. boost. Using the factory BP sensor (reads absolute) and catching a glimpse at the screen during a run looks like 1:1 to around 35 psi.

Don't bag on me to hard about my boots/clamps. I've been fighting boost leaks, and had the VCs off a couple times now..meant to change a couple of the boots/clamps around, but I'm holding boost for now..it's my only means...I'll get it squared away here in a bit.

Before install pics (click on first pic for a video)-

After install video-

http://www.youtube.com/watch?v=dwCRdHCZ5EM

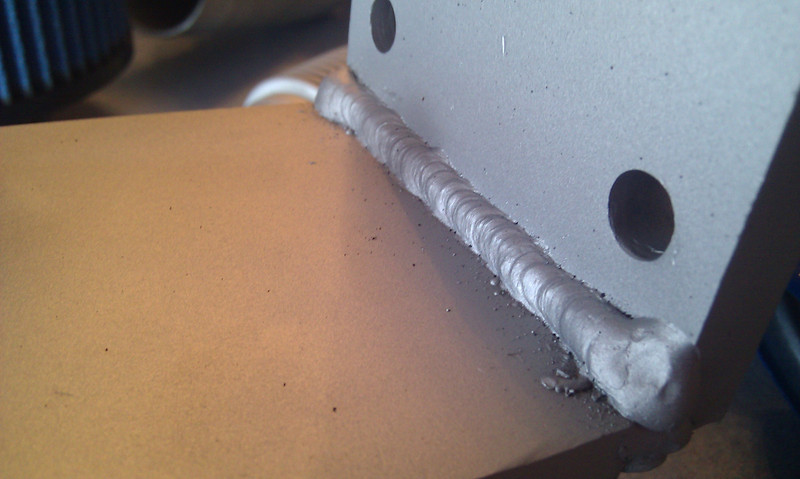

I think something that is worth mentioning to diyers is the tolerance on the base plate. It needs to be machined flat and thick enough not to distort under the weight of the turbo. I remember a thread a while back on the other forum about a guy that had an entirely too thin base and it wasn't machined flat. Huge oil leak.

I think something that is worth mentioning to diyers is the tolerance on the base plate. It needs to be machined flat and thick enough not to distort under the weight of the turbo. I remember a thread a while back on the other forum about a guy that had an entirely too thin base and it wasn't machined flat. Huge oil leak.

Its flat!

So just the two holes and you use the regular o rings...

So just the two holes and you use the regular o rings...